3D Printing

Materials guide

From strong plastics to polished metals, our materials

can bring your ideas to life.

Material

Description

Applications

Color & finishes

- Wide range of automotive, consumer, industrial and medical applications

- Excellent chemical resistance, low moisture absorption and long-term durability

Piping and fluid systems, Containers, Ideal for automotive (interior, exterior and under-the-hood)

- Gray

Attributes

- Chemical resistance

- Low moisture absorption

- High ductility

Technology

HP Multi Jet Fusion [MJF]

Material

Description

Applications

Color & finishes

- high strength, high elongation at break, high impact resistance

External medical devices, automotive, sports equipment, loaded functional prototypes, hinges

- White

- Gray

Attributes

- Chemical resistance

- High elongation at break

- High impact resistance

Technology

Selective Laser Sintering [SLS]

Material

Description

Applications

Color & finishes

- high strength & durability, good impact resistance, professional finish, thin features & interlocking parts

- HB rating (<75mm/min for thickness of 0.75mm)

- Dielectric strength value 2.8kV/mm, Volume Resistivity value 10^14 ohm-cm

Mechanical & structural parts, mounts, cases, eye frames, tech accessories, drone parts, home decor, miniatures, art, prosthetics

- Black – Deep Dye Black & Polyshot Surfacing

- Natural Gray – Polyshot Surfacing

Attributes

- High Strength, Durability

- Good impact resistance

- Heat deflection 95C / 203F

Technology

HP Multi Jet Fusion [MJF]

Material

Description

Applications

Color & finishes

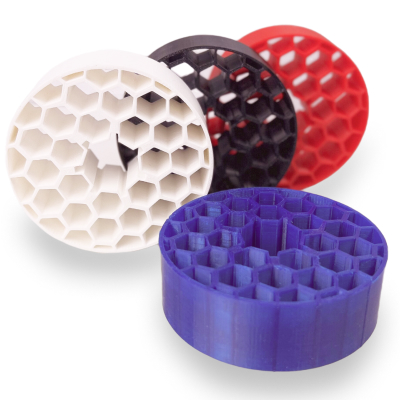

- high strength & stiffness applications, skin contact applications, thin features and interlocking parts

- HB rating (thickness greater than 0.5 mm)

- according to EN ISO 10993-1 and USP/level VI/121 °C

high strength & stiffness applications, skin contact applications, thin features and interlocking parts

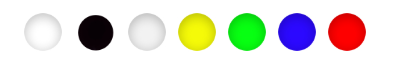

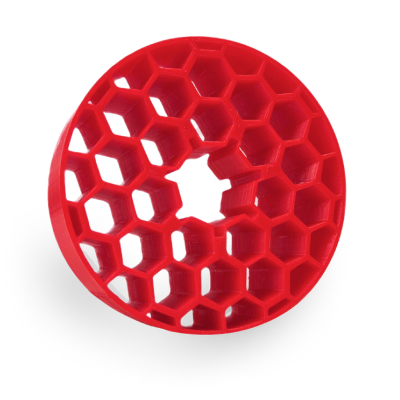

- White

- Natural

- Black

- Yellow

- Green

- Blue

- Red

Attributes

- High Strength, Durability

- Chemical resistance

- Affordable

Technology

Selective Laser Sintering [SLS]

Material

Description

Applications

Color & finishes

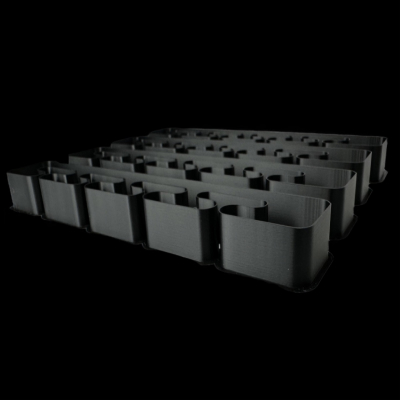

- Snappers, Connectors, Functional end-use parts

- Black appearance

- Excellent surface finishing

Functional prototypes, jigs & fixtures and very detailed parts

- Supports removed and lightly sanded

- Clear

- White

- Gray

- Black

Attributes

- Low water uptake

- Very high stiffness

- High Accuracy

Technology

Stereolithography [SLA]

Material

Description

Applications

Color & finishes

- Hyper PLA-CF offers high strength and exceptional layer adhesion, boasting superior physical and mechanical properties.

It strikes the perfect balance of strength, adhesion, and speed, with 30% higher mechanical properties than standard PLA in terms of flexural strength, flexural modulus, and impact strength.

Functional prototypes, jigs & fixtures and very detailed parts

- Black – Matte Finish

- Dark Green – Matte Finish

- Purple – Matte Finish

- Ochre – Matte Finish

- Greyish Yellow – Matte Finish

Technology

Fused Deposition Modeling [FDM]

Material

Description

Applications

Color & finishes

- Hyper Speed PLA represents the pinnacle of FDM technology, offering exceptional quality and performance.

This affordable option is easy to print and boasts outstanding strength and temperature resistance properties.

Functional prototypes, jigs & fixtures and very detailed parts

- White

- Black

- Gray

- Red

- Blue

- Green

- Orange

- Brown

- Beige

- Yellow

Technology

Fused Deposition Modeling [FDM]

Material

Description

Applications

Color & finishes

- Hyper Speed ABS thermoplastic nature of this material undergoes a carefully orchestrated heating process.

This transformative journey ensures that each layer seamlessly melds with the next, creating a solid and impeccable foundation for your designs.

Functional prototypes, jigs & fixtures and very detailed parts

- White

- Black

- Gray

- Blue

- Red

Technology

Fused Deposition Modeling [FDM]

Material

Description

Applications

Color & finishes

- TPU 85A boasts exceptional attributes that set it apart. Its remarkable resistance to hydrolysis ensures longevity, while its flexibility at low temperatures provides adaptability in diverse conditions.

Functional prototypes, jigs & fixtures and very detailed parts

- Natural

- Black

Technology

Fused Deposition Modeling [FDM]

Material

Description

Applications

Color & finishes

- PLA Premium It has excellent strength and temperature resistance properties.

PLA 3D printer is used to achieve matt finish and grainy texture.

Functional prototypes, jigs & fixtures and very detailed parts

- White

- Blue

- Black

- Orange

- Yellow

- Gray

- Green

- Red

Technology

Fused Deposition Modeling [FDM]

Material

Description

Applications

Color & finishes

- ABS Premium is material on its own has excellent wear resistance, elasticity, and great strength.

Functional prototypes, jigs & fixtures and very detailed parts

- White

- Black

- Gray

- Blue

- Red

- Orange

Technology

Fused Deposition Modeling [FDM]

Material

Description

Applications

Color & finishes

- PETG Premium is the polymerization addition to the raw Polyethylene terephthalate polymer.

Functional prototypes, jigs & fixtures and very detailed parts

- White

- Black

- Red

- Blue

- Yellow

- Green

Technology

Fused Deposition Modeling [FDM]

Material

Description

Applications

Color & finishes

- ASA Premium filaments are versatile thermo-materials that are suitable and versatile when used in 3D printing.

Functional prototypes, jigs & fixtures and very detailed parts

- White

- Black

- Grey

- Yellow

- Red

- Green

- Blue

- Dark Blue

Technology

Fused Deposition Modeling [FDM]

Material

Description

Applications

Color & finishes

- Nylon 6, 3D Print materials used for the replacement of functional moulded pieces with good corrosion tolerances.

Functional prototypes, jigs & fixtures and very detailed parts

- White

- Black

Technology

Fused Deposition Modeling [FDM]

Material

Description

Applications

Color & finishes

- PC/ABS FR provides exceptional tensile and impact strength, superior thermal resistance compared to ABS, and meets the stringent UL94 V-0 standard for flame retardancy.

Functional prototypes, jigs & fixtures and very detailed parts

- Black

Technology

Fused Deposition Modeling [FDM]

Material

Description

Applications

Color & finishes

- Nylon 6, 3D Print materials used for the replacement of functional moulded pieces with good corrosion tolerances.

Functional prototypes, jigs & fixtures and very detailed parts

- White

- Black

Technology

Fused Deposition Modeling [FDM]

Material

Description

Applications

Color & finishes

- TPU 92A is a thermoplastic polymer, with Shore-A values of 90. It is highly elongated, high toughness, strong durable and strong.

Functional prototypes, jigs & fixtures and very detailed parts

- White

- Black

- Red

- Blue

Technology

Fused Deposition Modeling [FDM]

Material

Description

Applications

Color & finishes

- TPU-95A is a flexible, durable 3D printing filament with rubber-like elasticity and strong impact absorption. Ideal for parts needing both flexibility and strength, it excels in demanding conditions with excellent abrasion resistance and elongation.

Functional prototypes, jigs & fixtures and very detailed parts

- White

- Black

- Grey

- Yellow

- Orange

- Blue

- Light Blue

- Purple

- Green

Technology

Fused Deposition Modeling [FDM]

Material

Description

Applications

Color & finishes

- 17-4 PH Stainless Steel – is hardware flexibility, low manufacture, and maintenance cost make the 3D metal FDM system the ideal choice.

Lead Time 2 weeks, Low-cost, good quality

- Silver

Technology

Fused Deposition Modeling [FDM]

Material

Description

Applications

Color & finishes

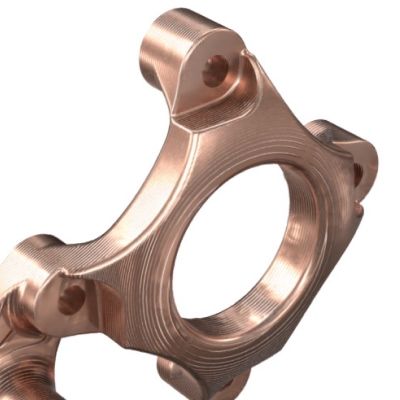

- Copper is structurally stronger, hard, and has higher elongation in contrast to aluminum alloys as well as metallurgical and electrical conductivity properties

Lead Time 2 weeks, Low-cost, good quality

- Brown

Technology

Fused Deposition Modeling [FDM]